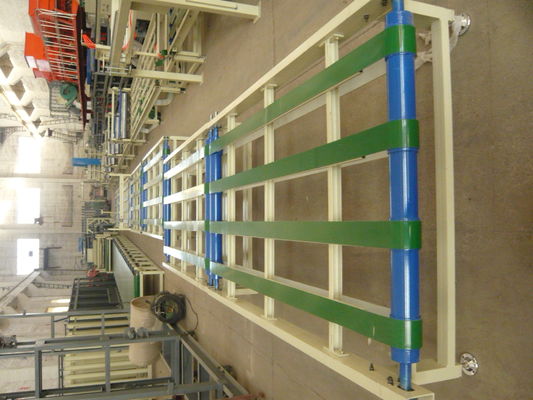

Máy làm ván Mgo kiểu lăn hai kênh cho ván Mgo dày 2 - 60mm

Dây chuyền sản xuất tấm mgo với công suất lớn hơn 1500 tấm

Dây chuyền sản xuất ván MGO / máy làm ván mgo / máy làm ván magiê oxit

Chỉ số kỹ thuật:

1. Chỉ số oxy%: 90

2. Đốt cháy cấp độ: SO

3. Đốt cháy theo chiều dọc: SO

4. Tỷ lệ hàm lượng nước: 10.9%

5. Dung tích: 1.15g/cm3

6. Cường độ uốn tĩnh: 169.46Mpa

7. Mật độ: T/ m3 1.13

8. Khả năng chống nước: Không bị phấn hóa trong 24 giờ và không có sự thay đổi trên bề mặt

9. Không có “Ba chất thải” (nước thải, khí thải và cặn thải), không gây ô nhiễm và

bảo vệ môi trường

3. Chỉ số kỹ thuật của sản phẩm

|

Chỉ số kỹ thuậtcho ván thành phẩm

1. Chỉ số oxy%: 90

|

2. Đốt cháy cấp độ: SO

3. Đốt cháy theo chiều dọc: SO

4. Tỷ lệ hàm lượng nước: 10.9%

5. Dung tích: 1.15g/cm3

6. Cường độ uốn tĩnh: 169.46Mpa

7. Mật độ: T/ m3 1.13

8. Khả năng chống nước: Không bị phấn hóa trong 24 giờ và không có

sự thay đổi trên bề mặt

9. Không có Ba chất thải (nước thải, khí thải và cặn thải), không gây ô nhiễm

và bảo vệ môi trường.

4. Ưu điểm của máy

|

a. Khả năng chống nước: Không bị phấn hóa trong 24 giờ và không có sự thay đổi trên bề mặt

b. Không có “Ba chất thải” (nước thải, khí thải và cặn thải), không gây ô nhiễm và bảo vệ môi trường.

Công nghệ sản xuất: Máy cán, đúc, cán, bảo quản, halogen hóa, rửa, sấy, dán bằng tấm poly (nếu khách hàng yêu cầu), cố định chiều dài và chiều rộng, vát cạnh (nếu khách hàng yêu cầu), đóng gói

Tính năng: Không mùi và không độc, không dễ cháy, không khói, cường độ cao, chất lượng nhẹ, cách âm, bảo quản nhiệt, chống thấm nước, chống cháy, không bị đóng băng và xói mòn, tỷ lệ co giãn và co ngót nhỏ, không nứt và biến dạng, thi công thuận tiện, ít hao phí và tuổi thọ cao, v.v.

Ứng dụng: Có thể áp dụng cho vách ngăn và trần treo trong trang trí các tòa nhà, cấu trúc cho tường cách nhiệt cách âm, những nơi ẩm ướt, vách ngăn di động, phòng cháy chữa cháy đặc biệt, tấm kẹp trong cửa chống cháy và bao bì của các hộp thiết bị.

Tên thiết bị

Hệ thống kiểm soát liều lượng

Hệ thống quay mẻ tự động

Hệ thống điều khiển vi tính

Hệ thống thu gom bụi

Hệ thống vận chuyển nâng

Hệ thống phân phối điện

Hệ thống trộn vải vỏ

Hệ thống trộn vật liệu trung gian

Hệ thống trộn bột giấy

Hệ thống sàng lọc phụ kiện

Hệ thống hòa tan chất kết hợp

Hệ thống hòa tan chất kết hợp và đo lường tự động

Hệ thống tạo hình

Hệ thống điều khiển khí nén chân không

Hệ thống khuôn tự động

Hệ thống vận chuyển tạo hình

Hệ thống tạo hình lăn

Hệ thống cắt ván tự động

Hệ thống thu gom ván tự động hai thang máy

Hệ thống điều khiển cảm ứng máy tính

Đường thanh tốc độ

Hệ thống thay đổi đường ray xe tải

Hệ thống bảo dưỡng

Hệ thống nhiệt độ không đổi trong phòng bảo dưỡng

Hệ thống kiểm soát độ ẩm tự động trong phòng bảo dưỡng

Hệ thống tước tự động

Hệ thống xếp chồng ván tự động

Xe nâng

Hệ thống sắp xếp ván

Hệ thống vận chuyển đường thanh

Máy cắt tốc độ cao theo chiều ngang và chiều vuông góc

Băng tải định hướng cảnh quan

Máy chà nhám

Hệ thống thu gom bụi

Hệ thống tự điều khiển vi tính

Hệ thống phân phối điện

1. Dây chuyền sản xuất có thiết kế tốt, cấu trúc hợp lý, vận hành ổn định và sử dụng hệ thống kiểu lăn hai kênh. Nó được tạo hình trong một lần và có độ dày ổn định. Ngoài ra, nó có năng suất cao hơn. Với một thiết bị rung, nó loại bỏ các bọt bên trong và bên ngoài. Nó có thể sản xuất ván MOG dày 2-60mm. Và chiều rộng nhất là 1300mm, đối với chiều dài, không có giới hạn và có thể điều chỉnh độ dày theo yêu cầu.

2. Thiết bị có thể có nhiều công dụng. Nó có thể sản xuất ván tro mô phỏng, ván gỗ du đỏ/trắng giả, tấm gỗ sồi, ván cửa cứu hỏa, ván trần và tranh tường, v.v.